News

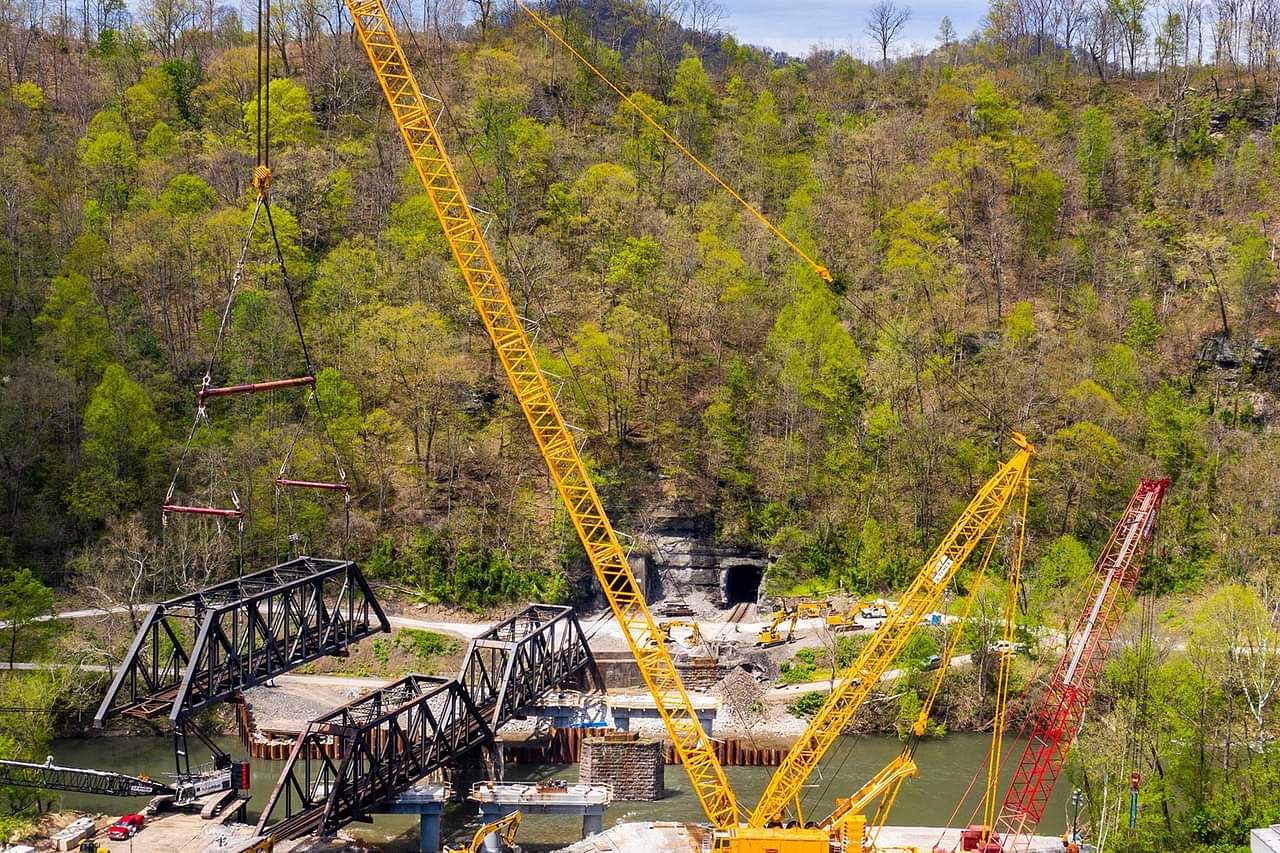

Bridge Span Move and Lift Set Pace for New Bridge Completion

Posted: 04/30/2021

In support of a major bridge construction project in the Midwest, Deep South crews helped transport and install eight bridge spans from an off-site staging area to the bridge foundation. The heaviest of the eight spans was 820,000 pounds and measures 143’ long, 13’ wide, and 10’ high and total transport weight was 1,020,000 pounds.

Hydraulic Emphasis

The job was completed in two phases using two different trailer configurations to accommodate complicated areas along the route.

In addition, Deep South designed and provided support equipment between the hydraulic transporter and bridge beams to allow for transport and installation at the proper height. This allowed Deep South to install each span using only the hydraulics of the transporters, thus eliminating the need for additional jacking equipment.

Trailer configurations included two 6-axle-line Scheuerle SPMTs with 200-ton bolsters to support span ends and one 16-axle-line Scheuerle SPMT-SL (Split) trailers with static cribbing supporting the span’s center.

This first phase included the first four of the eight bridge spans. Picture at right is the heaviest span of the first phase, weighing 601,000 pounds and measuring 143' long, 13' wide, and 10' high. This phase was completed in 2019.

Bolstered for Maneuverability

The second phase was completed in 2020. Four bridge spans — the largest of which was 820,000 pounds and measured 143’ long, 13’ wide, and 10’ high — were staged for self-loading with help from Deep South’s engineering expertise. Three of the spans were transported and set utilizing the split-single-wide 16-axle-line SPMT. Due to the bridge design, the fourth span required bolsters for additional maneuverability during installation.

For span four, Deep South utilized two SPMTs (a 10-axle-line and an 8-axle-line) to transport and set. Once ready for transport, the SPMT was moved into position under the bridge spans. Using the SPMT’s hydraulics, the spans we lifted and transported 1/8 of a mile to the final set location. Using the SPMT hydraulics, which eliminated the need for additional jacking equipment, the bridge spans were lifted on to the 11’ high piers.

The total transport weight was 1,020,000 pounds.

CLICK HERE TO LEARN MORE ABOUT THIS PROJECT

----------

About Deep South: Deep South Crane & Rigging is a leading provider of heavy lift and transport solutions in the refining, chemical, and energy sectors and strives to provide its customers the best tools to complete the task at hand and is home of the VersaCrane fleet. The firm offers a complete range of services, from bare crane rental to turn-key heavy lift and transport solutions to clients in North and South America. It operates out of 7 locations including Baton Rouge, LA; Sulphur, LA; New Orleans, LA; Dequincy, LA; Beaumont, TX; Houston, TX; and Catlettsburg, KY. Sister company DS Americas operates out of Bogota, Colombia. Recent recognition includes 2018 Houston Business Roundtable (HBR) Best of the Best Safety Excellence Award, 2019 Mentor Award, and 2020 Finalist; 2018 Industrial Safety Training Council (ISTC) Safety Achievement Award; 2018 and 2020 Greater Baton Rouge Industry Alliance (GBRIA) Contractor Safety Excellence Award, Crane & Rigging; 2019 Greater Baton Rouge Industry Alliance (GBRIA) Workforce Development Best of Division OneAward; 2018 and 2019 Specialized Carriers and Rigging Association (SCRA) Safety Award; and 2018, 2019 and 2020 Louisiana Worker's Compensation Corporation (LWCC) Safest 70)

Super-Sized Truss No Problem for High Capacity Crane

Posted:05/03/2021

A residential backyard, a nearby interstate, and a limited work window all combined to make a bridge truss replacement project a powerful demonstration of lifting strength and agility.

Custom Connections Deliver Heavy Systems Safely, Timely, and Cost Effectively

Posted:01/12/2021

Deep South has put its transport and skills to work for a heavy industrial project in the Southwest that required Deep South to direct discharge from ships gear to barge, haul and sett a cold box, depropanizer and six modules.