Relocation & Decommissioning

Deep South is a knowledgable provider of industrial plant decommissioning & relocation services.

We know business owners and their teams spend a considerable amount of time and energy on the details of moving to a new location or decommissioning dated facilities. Whether it is a small project area or a complete relocation of a large plant, Deep South offers a complete turnkey plant relocation solution.

Our Comprehensive Turnaround and Shutdown Services Include:

Feasibility Studies & Constructability Reviews: We collaborate with our clients to perform feasibility studies and route studies to determine the most efficient and safe lift and transport solution.

Estimating and Scheduling: We join forces with our clients to efficiently plan all proposed job site activities.

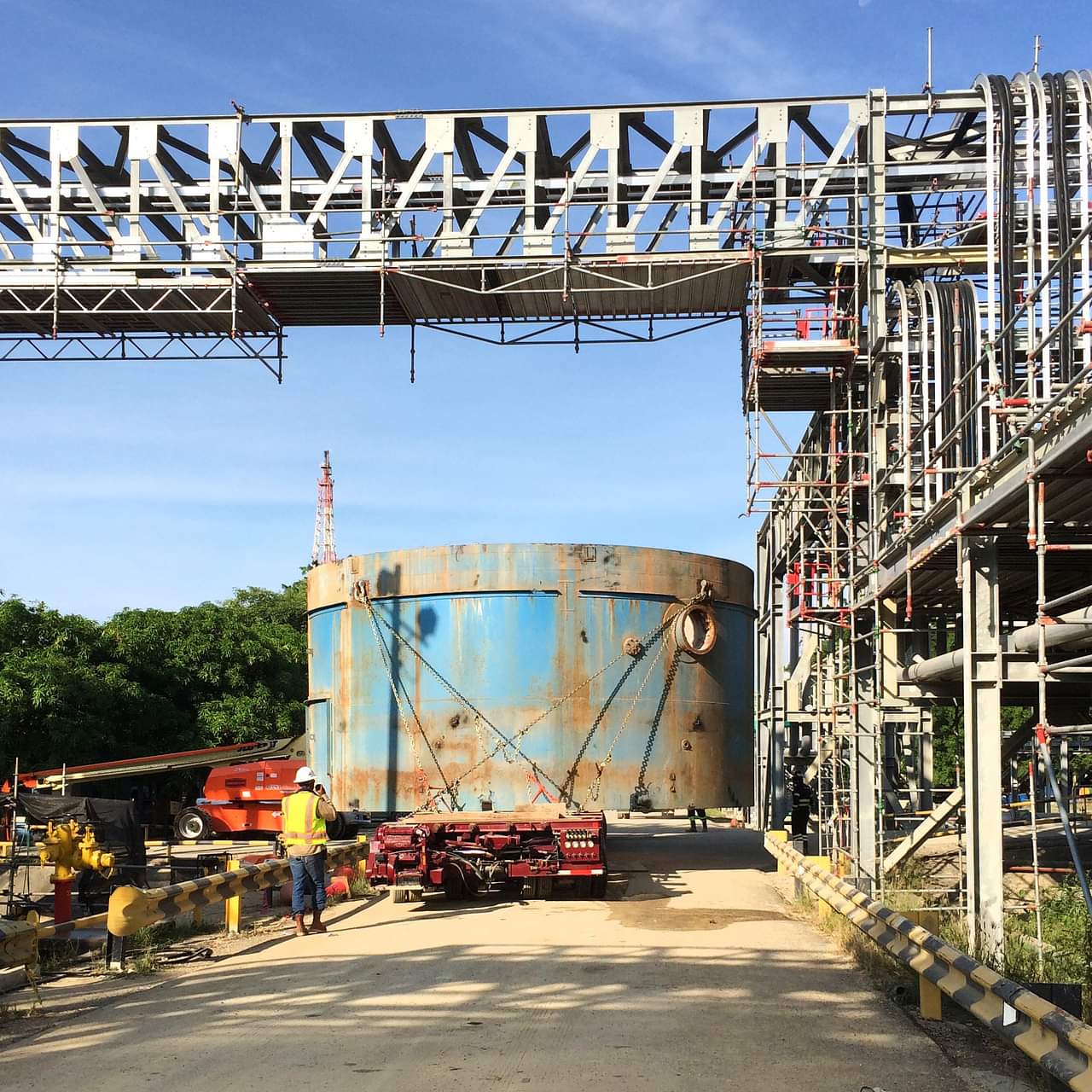

Site Planning and Execution: We offer our expertise to select the best transportation methods (whether onsite, road, barge, rail, or waterborne) and overcome challenges (such as clearances, weights, access, permits), and we develop and propose equipment schedules, permitting plans, lift plans, etc.

Logistics Planning: We evaluate and develop plans to address support facilities, lay down yards, heavy-haul traffic flow, and material transport.

Safety Planning: We evaluate and develop job-specific safety plans when necessary, comply with all site requirements and applicable laws.

Robust Planning & Overcoming Obstacles

Robust planning is the key ingredient to having a successful project. When you bring Deep South in as a partner, you acquire years of experience in properly planning an outage will minimize downtime and keep the project on track to completion. Nevertheless, unexpected issues may arise, and we at Deep South are well-equipped to take an engineered approach to solving project challenges.

- Project solutions are created by a team of certified Professional Engineers and experienced craftsmen who can respond quickly to project needs.

- Our fabrication facilities total nearly 100,000 square feet.

- The facilities are equipped with the tools needed such as a state-of-the-art robot welder, CNC tables, lathes, boring machines, radial drilling machines, cutting tables, saws, and multi-process welders.

- 24-hour crews are available.

Deep South has a large fleet of equipment to allow the movement of vessels to wherever they need to be set, including VersaCranes™ to 3,000T, crawler cranes to 1,760T, truck cranes to 1,320T, and rigging hardware/specialty devices up to 1,600T. Deep South also has self-propelled modular transporters, over-the-road/dual-lane transport systems, towed hydraulic modular transporters, temporary bridge systems, levee crossing systems, lift towers, strand jacks, hydraulic gantries, hydraulic skid and hydraulic jacking systems, and marine and rail securement systems.

From our experienced engineers and project managers to our skilled craftsmen, riggers, and crane operators, Deep South's diligent pursuit of safety and innovation has provided our clients a path to on-time and successful projects. We can create lift plans or PE-stamped drawings and custom solutions as needed. Leaning on this expertise, coupled with a broad array of equipment, helps us to provide the absolute best in safety, service, and solutions. Whatever the project, the team at Deep South is ready to meet your challenge.

Projects

Southeast Petrochemical Turnaround

View Project

Southeast Petrochemical Turnaround

Supplying all cranes in two units during a petrochemical turnaround in the Southeast, Deep South supported the change out of old components and reinstallation of new components with 19 cranes working throughout the project.

Precision in Motion

View Project

Precision in Motion

The Deep South team was tasked to transport a 1,230,000-pound reactor (29'-10" diameter, 120' tall) and a 314,000-pound regen head (37'-5" diameter, 75' tall) from a manufacturing facility in Northeast Mississippi to a refinery in Louisiana.

Complex Refinery Turnaround Delivered with Precision

View Project

Complex Refinery Turnaround Delivered with Precision

A five-week equipment turnaround at a refinery in the Southeast required multiple equipment transports, removals, and replacements across a large work area.