Resources

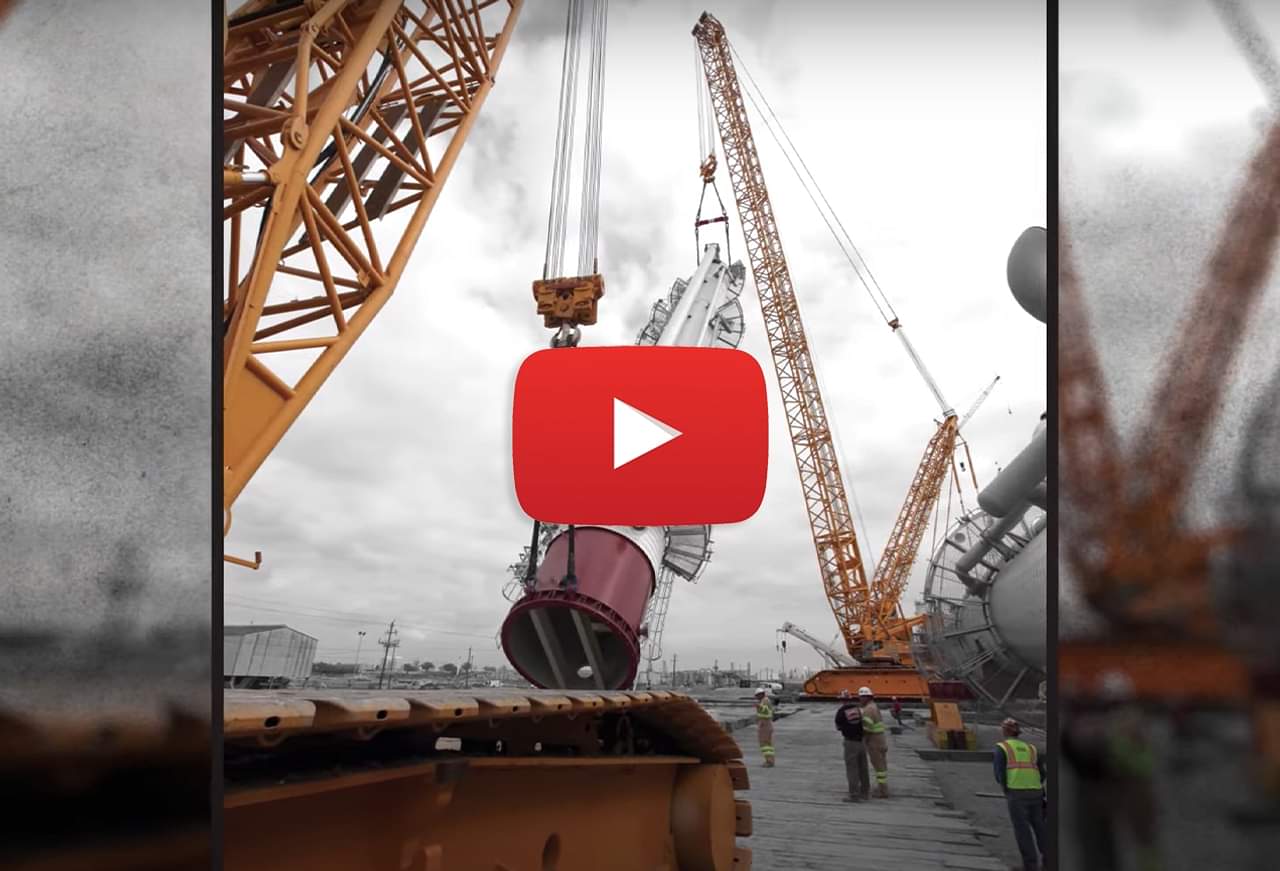

A Technical Towering Roll, Move & Lift

The transport of a new vacuum tower (weighing in excess of one million pounds) was the first part of a complex, multi-phase project that required two years of planning. The tower was received from ship’s gear onto a prepped barge that was then pushed to the Texas City Dock. After the marine transport was complete, Deep South used a double-wide 18-axle-line Scheuerle SPMT to move the 114’-7” x 33’-5” x 39’-10” tower and set it on temporary staging for dress out and prep work Months later, Deep South returned to transport the tower from the staging area to the crane area. The move required transportation over a sleeper rack utilizing Deep South’s 100’ jumper bridges, in combination with planned timber matting, to climb down a 6’ elevation change from the staging area to the lifting area. Deep South then weighed the tower using a Straightpoint Bluetooth Weighing System. Finally, Deep South set the tower using the 1,000-ton VersaCrane™ CC-12000 and a 440-ton Tadano Demag CC-2400-1 for tailing.

Turnkey in Tight Quarters: Deep South's Split Trailers Reduce Height with Inches to Spare

For a petrochemical refinery in the Southeast, Deep South moved two 491,000-pound coke drums measuring 99’ long and 24’2” diameter from Spain to the client’s site in Louisiana. Along the way, Deep South solved many complex challenges, including coordinating international shipping, trans-loading the drums to a deck barge at the port, barging them to the client’s site, constructing a custom earthen ramp, and executing the roll-off operation. Once inside the plant, the job became even more complicated as we had to navigate a critical main-line rail crossing in 9 hours while putting no weight on the tracks – and also while bridging a tunnel and encountering numerous limiting height and width requirements, some with only 2” of clearance. Equipment used included 12-axle lines of double-wide Scheuerle SPMT, 10-axle lines of Scheuerle Split SPMT, barge ramps, 80’ jumper bridges, jack and slide equipment, and jacking cans.

Deep South's 124-line SPMT Chemical Reactor Transport

In the Southwest, Deep South received three vessels from a heavy lift ship at the Port of Houston, barged the vessels, and transported them to final staging using a total of 124-axle lines Scheuerle SPMT. The heaviest vessel weighed 1,800,000 pounds and the total gross weight at transport for that vessel was 2,300,000 pounds.No roll-off site was available, so Deep South identified a potential roll-off location, executed a lease agreement, cleared the land of trees, brought in dirt and compacted the area, and added a temporary dock using matting and steel ramps. The barging was performed in two conveyances using 3 barges and 3 tugs.

Deep South's 500,000-pound Deisobutanizer Turnkey Project

Deep South Crane & Rigging performed turnkey transport and lift services for a Southeast oil refinery, transporting a 500,000-pound deisobutanizer from its fabricator in Vicksburg, Mississippi to Krotz Springs, Louisiana using a combination of over-the-road hauling, barging, and heavy lifting. The 1,500-ton VersaCrane TC-24000 as well as the 440-ton Demag CC-2400 lifted it into final position. Lifting bails with all steel-plate links allowed the crane operator to unhook the rigging without any personnel having to access the top of the tower.

Deep South Crane hosts 650 students at Lift and Move USA Event

Deep South Crane hosted Louisiana's first Lift and Move USA event in Baton Rouge, Louisiana, partnering with KHL, SC&RA and Berard Transportation to help develop tomorrow's Heavy Hitters in the crane, rigging, and specialized transport sectors.

Deep South Crane - Heavy Hitters

Deep South challenges you to put your mechanical mind to work and become a part of America's next generation of HEAVY HITTERS.

Deep South's Roadmap To Safety

Deep South Crane & Rigging, in a Baton Rouge refinery, safely executed a 315,000 pound critical lift using our 1000T VersaCrane CC-12000. Proving that proper planning and good safety efforts go hand in hand.

Deep South Specialized Fabrication Capabilities

Specialized fabrication has always been a key component of Deep South Crane & Rigging’s ability to provide turnkey solutions to our customers, but did you know that this equipment is also available for rental on your project? This video will walk you through our steel distribution systems, moment connection bridge ramps, temporary bridge systems, bolsters, and barge ramps, all of which will bring additional strength, efficiency, and safety to your project.

Deep South Crane and Rigging's Bridge Jack Up System

Through our years of over-the-road hauling, Deep South has been tasked by our clients to provide a solution to the problems posed by deploying bridge ramps using assist cranes. Deep South's bridge jacking system not only eliminates assist cranes; it saves time on the schedule, lowers cost and minimizes the footprint.

2015 Year in Review

In Deep South's world, a lot can happen in a year and 2015 was no exception. See how we've engineered and executed solutions for complex challenges in this 2015 Year In Review.

Overcoming Obstacles: Deep South's Superior Jack and Slide Capabilities

With nearly 50 years of experience in the heavy lift and heavy haul industry, Deep South can overcome even the most challenging obstacles. At a refinery in the Midwest, extreme spatial constraints and underground utilities offered little room for error. Deep South met this challenge by executing an 800' jack and slide operation, which allowed the vessels to overcome extremely low ground bearing pressures, less than 2".

Deep South Transport Job - 800-ton Quench Tower Section

As part of a major expansion project in Texas, Deep South received, barged, and transported this 800-ton Quench Tower Section. Utilizing our 1000-ton rocking bolsters, in-house designed transport saddles, and 120’ Bridge Ramps, Deep South was able to negotiate the barge rolloff and 4 miles of roadways through a town to reach the job site. This included crossing 3 jumper bridges, the longest measuring 120’ in length. The vessel shown in this video was the largest of the 37 vessels that Deep South received, barged, and transported to complete this project.

Deep South's 2,500-ton VersaCrane TC-36000 Highlighted in Ecopetrol Video (with English Subtitles)

Deep South's sister company, DS Americas successfully completed its first international project in 2013. We are proud of this accomplishment and look forward to continued growth in Latin America and Canada.

Auquarena Springs Submarine Theater Lift using Deep South's 1,800-ton VersaCrane TC-28000

The 520T Submarine Underwater Theater, a former tourist attraction, was removed from Aquarena Springs theme park by the VersaCrane TC-2800 using 273' of main boom at a 110' radius. The removal of the underwater theater was critical due to the environmental impact it was having on the area, which is home to 8+ endangered species.

Deep South's 2,500-ton VersaCrane TC-36000 Highlighted in Ecopetrol Video

Deep South's sister company, DS Americas successfully completed its first international project in 2013. We are proud of this accomplishment and look forward to continued growth in Latin America and Canada.

2013 Year in Review

Take a look at real-world challenges we met head on in this project highlight reel from 2013.