A High Pressure Exchange

During a scheduled outage, Deep South was tasked to replace two coke drums at a refinery. The new drums each weighed 452,800 lbs and were 19’-2” outside diameter and 96’-0” long, comparable in size and weight to the old drums.

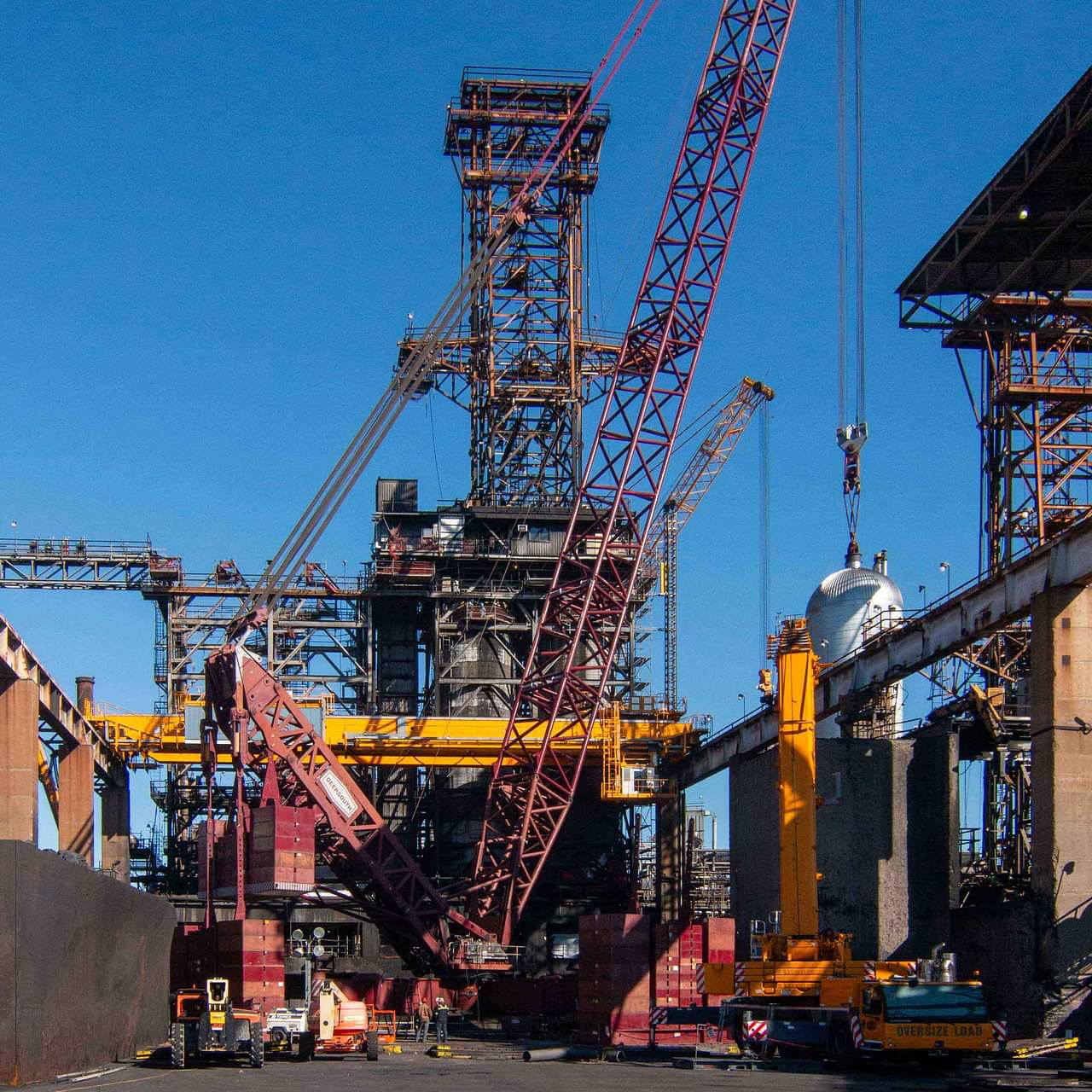

Completing the replacement within the window of time and in the tight confines required precise logistics, specialized crane configurations, and multiple means of transport. Notably, Deep South assembled the 1,500T VersaCrane™ TC-24000 off-site and moved the crane via SPMT, saving the client 15 days of downtime and allowing the refinery unit to run at full capacity until unit shutdown.

Readied for Install

A year prior to the outage, Deep South received the new coke drums from a ship at the Port of Houston and then barged them to a dock on the Calcasieu River in Louisiana. Once on location, the coke drums were rolled off of the barge and staged using the 440-ton Terex-Demag CC-2400-1 in SSL configuration with a 177.2’ main boom, 352.7kps auxiliary counterweight, and 529.1kps auxiliary counterweight along with a 500-ton Liebherr LTM1400-7.1 tail crane. Each drum was erected into the vertical position and placed in a jig stand to add insulation.

In advance of the refinery outage, Deep South relied on a 16-axle-line (48 tons per axle line) split SPMT with widening system for over-the-road transport of the new coke drums from barge site to the refinery. The team worked closely with a neighboring petrochemical facility so as not to disrupt operations.

Multiple Constraints

To remove the derrick structure and replace the coke drums, Deep South looked to its versatile VersaCrane™ TC-24000 in Configuration VI with a 310’ main boom as well as a 550kps main counterweight with 840kps hinge counterweight. The slope of the coke pit was a concern and a constraint, and if a crawler crane was used, it would require extensive civil work and matting, delaying the job. The client preferred not to use any rock in the pit, due to the amount of cleaning required post turnaround—a specification that effectively ruled out the use of any crawler crane because of the amount of matting/rock needed to level the crane.

The TC-24000 only required level matting under the outriggers and under the counterweight lift/set positions. Further, the crane capacity allowed all swing operations to be performed with only the main counterweight, which doesn't require any ground matting.

The tail swing clearance within the coke pit was also a major constraint at the site. The TC-24000 allowed the team to only utilize the hinge counterweight tray, which has a tighter tail swing than other super-lift cranes of that same tonnage class. Therefore, the Deep South crew was able to shift the crane in the pit off-center and stage all of the new components on the same side of the coke pit wall while maintaining tail swing clearance from any obstructions within the pit—effectively reducing site impacts during turnaround activities.

The final challenge was to manage the allowable ground bearing pressure on the sluiceway pit wall. There is a pit with a wall, located between the crane set up location and the locations where lifts in the structure occurred, that had been previously damaged during unit operation. This wall would have required shoring if the crane's ground bearing pressure had been too high. The VersaCrane™ TC-24000, with its low ground bearing pressures, eliminated the need for wall shoring, saving the client significant time in site preparation prior to the crane performing its lifts.

A Crane Move First

To allow the refinery unit to keep running at full capacity until unit shutdown, the crane needed to be assembled off site and moved into position when ready—an operation that Deep South had never done. Performing this move required significant cooperation between the project engineering and VersaCrane™ design engineering teams. Understanding crane stability during transport required detailed calculations with weights of every component installed on the crane to determine a composite center of gravity for the crane. The transporters were sized to guarantee crane stability during the move, meet low ground bearing pressure site requirements, and allow the transporters to maneuver tight clearances on a congested site.

The result was a tailor-made transport plan of the crane designed exactly to the client's needs.

The transport of the crane from its assembly/staging position to its final lift position took approximately one hour. In total, the off-site assembly saved approximately 15 days when considering mobilization, assembly, disassembly, and demobilization.

Operational Flexibility

After unit shutdown was complete, the Deep South crew moved the fully-assembled VersaCrane™ TC-24000 into final lifting position with the boom in the air—a company first—to begin the derrick cutting and coke drum exchange using two 18-axle-line (48 tons per axle line) Scheuerle SPMTs.

The crane measured 47’-6”L x 47’-6”W x 295’-3”H and weighed 1,607,250 lbs. (1,985,850 gross load w/ trailers). The derrick structure was 481,800 lbs and 69’-6”L X 32’-0”W X 127’-10”H, sitting at an elevation of 228’-1”.

The drums were removed and set onto a 12-axle-line Goldhofer E-Series for in-plant transport of existing/old coke drums, transported to the laydown area, and offloaded using a 700-ton gantry jack system for later disposal. Once the new coke drums were placed, the derrick structure was reset.

So as not to delay unit start up, Deep South transported the fully-assembled VersaCrane™ TC-24000 back to a nearby laydown area for disassembly and demobilization when the coke drum exchange was complete.

-

Equipment Used

-

Services Used