Custom Solutions

We Can Design, Build, and Test Specialized Lifting and Transport Equipment to Meet the Needs of Your Project

Our work typically presents us with many challenges. We can tackle these challenges through our creative engineering and extensive fabrication capabilities. Quality is assured through many methods including finite element analysis, computer modeling and analysis, non-destructive testing, proof loading, and pull-testing.

Examples of our solutions to tough project challenges include:

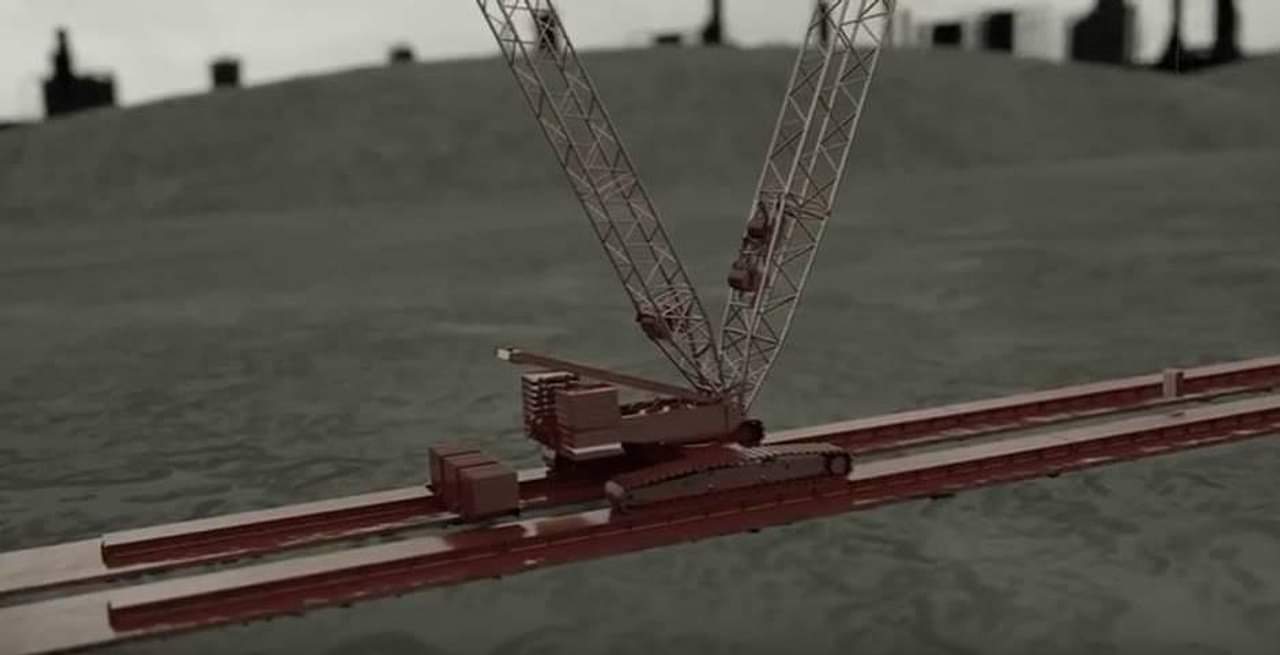

- River levee crossing bridge (capacity >1,000 tons)

- Bridge jumpers through 100’ span

- Hydraulic jacking, skidding, and gantry systems

- Lift towers and strand jacks

- Low-profile, inverted saddle systems (for minimizing transport height)

- Hydraulic adjustable spreader bars and lift beams

Projects

Southeast Petrochemical Turnaround

View Project

Southeast Petrochemical Turnaround

Supplying all cranes in two units during a petrochemical turnaround in the Southeast, Deep South supported the change out of old components and reinstallation of new components with 19 cranes working throughout the project.

Precision in Motion

View Project

Precision in Motion

The Deep South team was tasked to transport a 1,230,000-pound reactor (29'-10" diameter, 120' tall) and a 314,000-pound regen head (37'-5" diameter, 75' tall) from a manufacturing facility in Northeast Mississippi to a refinery in Louisiana.

Complex Refinery Turnaround Delivered with Precision

View Project

Complex Refinery Turnaround Delivered with Precision

A five-week equipment turnaround at a refinery in the Southeast required multiple equipment transports, removals, and replacements across a large work area.