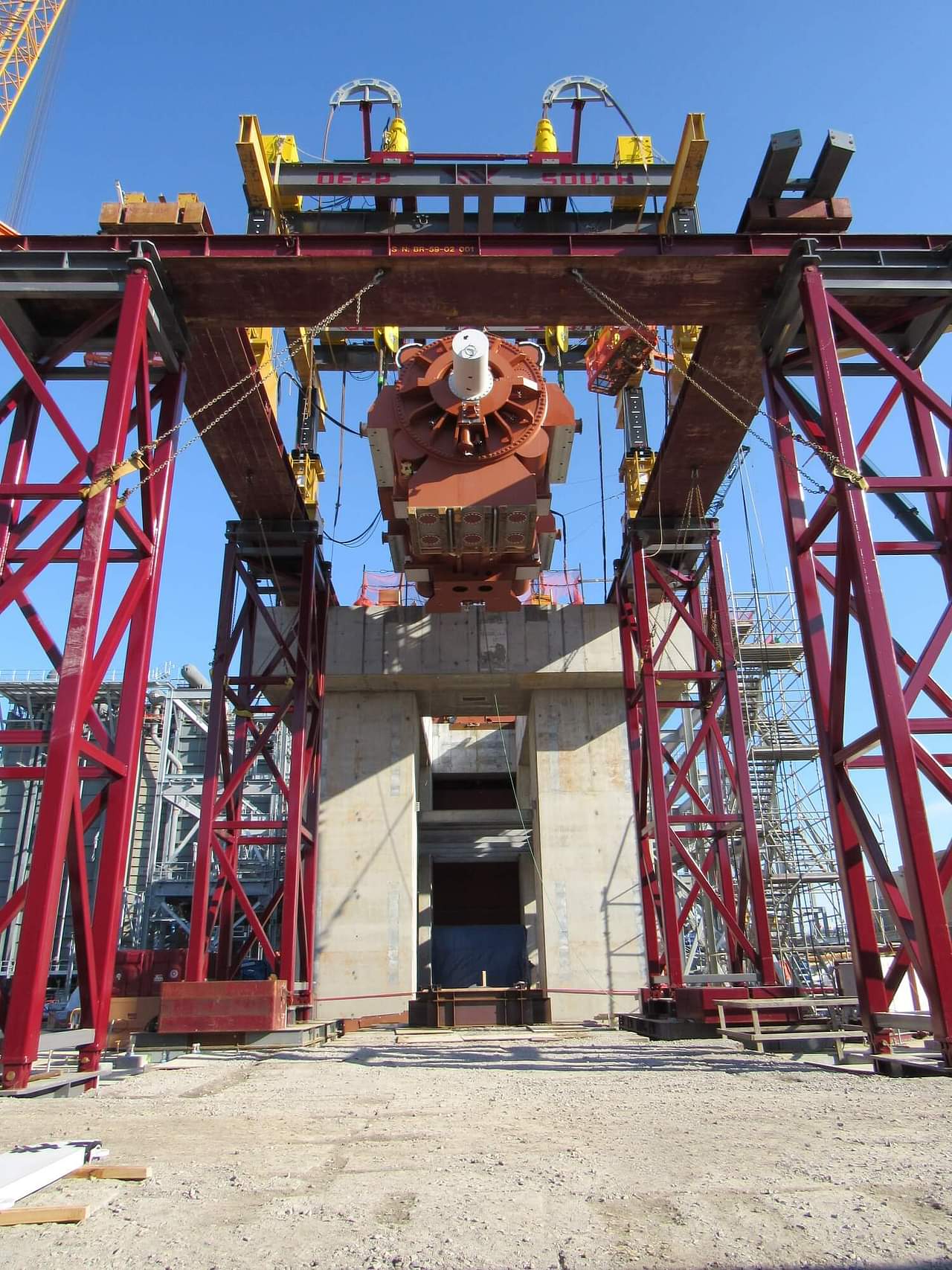

Combined Gantry/Strand Jack Systems Power Lifts Co-Gen Train

The construction of a combined-cycle power station in Louisiana required a specialty contractor to move, lift and set a STG generator (692,250 lbs.) and HIP turbine (392,420 lbs.).

Conventional approaches using a large crane required too much space, limiting other construction activities from continuing near the generator and turbine erection site. As an alternative, Deep South Crane & Rigging engineered a customized solution that enabled one continuous lift of both the generator and the turbine in a contained space. The solution combined a 650-ton Lift System gantry with an in-house designed tower system and 500-ton Enerpac strand jack system. In addition, the system also included Deep South’s Strand Jack Header Beam System with hydraulic side shift capability.

Crews used a double-wide SPMT transporter with a small “Piccolo” PPU to maneuver the generator and turbine each into position under the gantry. Once positioned under the gantry, the strand jacks lifted the equipment 40’ to the elevation of the tabletop. Then crews propelled the gantry the necessary distance over the set location. For the turbine, the gantry system traveled a little over 122 feet, while the generator was moved a little over 56 feet.

When positioned over the set location, Deep South used the gantry to lower the equipment into place while the strand jack header beam system facilitated side shift as needed for final alignment. Deep South performed all engineering associated with the lifts including stability calculations, structural design of the system, and lift drawings.

The rigging crew completed the job safely, saving the client money and time while also allowing construction to continue adjacent to the lift location.

-

Equipment Used

- Scheuerle SPMT

- Strand Jacks/Lift Towers

- Hydraulic Gantries

-

Services Used

-

By the Numbers

- 692,250-pound SGT Generator

- 392,420-pound HIP Turbine

Related Projects

Tailing Over a Live Pipe Rack Emphasizes Complex Project

View Project

Tailing Over a Live Pipe Rack Emphasizes Complex Project

From a tricky bridge crossing to a complex coordinated lift, Deep South facilitated the delivery and setting of components for a petrochemical facility acid modification and upgrade project in Louisiana. The key components included a 627,000-pound acid settler, 689,000-pound first stage reactor, acid storage drums and associated parts.

Bridge Limits: Deep South Facilitates Complex Multi-Stages Delivery of Million Pound Converter

View Project

Bridge Limits: Deep South Facilitates Complex Multi-Stages Delivery of Million Pound Converter

In preparation for a capacity expansion project, Deep South transported a 939,327-pound ammonia converter shell from the manufacturer to its plant in Donaldsonville, La. The trek required moving the system about 135 miles by water to a barge unloading site and 30 miles over the road.

Extreme Circumstances Call for Extreme Measures: A Narrow Canal Requires a Side Roll-Off

View Project

Extreme Circumstances Call for Extreme Measures: A Narrow Canal Requires a Side Roll-Off

Deep South was contracted to deliver a 750,000-pound reactor to a refinery in northern Illinois. The navigable waterway, a highly-trafficked 125-foot wide canal, required a side roll-off.