PROJECTS

Throughout our nearly five decades of experience in heavy lift and transport solutions, we have learned that a successful job is built on precise planning and safe execution. This mindset has allowed our business to grow and positively impact some of the most complex projects across two continents. Take a look at what we can do.

- Projects Filtered by:

- TC-28000

- Clear Filters

Saddle Up: Customized Solutions Place Refinery Column with Care

View Project

Saddle Up: Customized Solutions Place Refinery Column with Care

The Deep South team was tasked to receive, transport and set a 790,025-pound debutanizer. This specialized distillation column measures 174’-3” long with a 21’-3” diameter. The debutanizer was received from an ocean-going vessel at the Port of New Orleans. Once cleared through customs, the debutanizer was loaded on a barge and pushed to a roll-off site 8 hours upriver, and prepared for transport to the refinery.

Customized Heavy Lift Solution Safely Delivers Regenerator

View Project

Customized Heavy Lift Solution Safely Delivers Regenerator

Limited space, low ground bearing pressure and a cumbersome heat exchanger combined to create some unique challenges for the Deep South team in California. The customer needed to lift a 35’-diameter x 70’-long regenerator head with cyclones, weighing 775,000 pounds in a tight, geologically compromised area.

Transporters and Cranes Facilitate Processing Plant Upgrade

View Project

Transporters and Cranes Facilitate Processing Plant Upgrade

The movement and replacement of process plant components are a familiar site in in the Texas Gulf Coast region—though not often to the scale and timeline faced by one EPC contractor. Per the client, the contractor was tasked with the haul and lift of two trains of fractionation tower components (debutanizer, depropanizer, splitter and deethanizer) over the course of nine months.

4 Drum Coker Unit

View Project

4 Drum Coker Unit

Deep South was contracted to complete a full replacement of a four-drum coker unit.

Dismantling and Relocating A Petrochemical Facility

View Project

Dismantling and Relocating A Petrochemical Facility

Deep South was contracted to dismantle and relocate 9 vessels from a petrochemical plant using a combination of barging, heavy transport, and heavy lift services.

Overcoming Obstacles: 800-mile Turnkey Challenge with Notable Jack and Slide

View Project

Overcoming Obstacles: 800-mile Turnkey Challenge with Notable Jack and Slide

Using its nationwide resources, Deep South transported a reactor and third stage separator from Oklahoma to Ohio and then to its final destination in the refinery using a combination of barging, over-the-road transportation, jack and slide operations, and heavy lifting.

Southeast Petrochemical Turnaround

View Project

Southeast Petrochemical Turnaround

Supplying all cranes in two units during a petrochemical turnaround in the Southeast, Deep South supported the change out of old components and reinstallation of new components with 19 cranes working throughout the project.

A Marathon Job, Literally

View Project

A Marathon Job, Literally

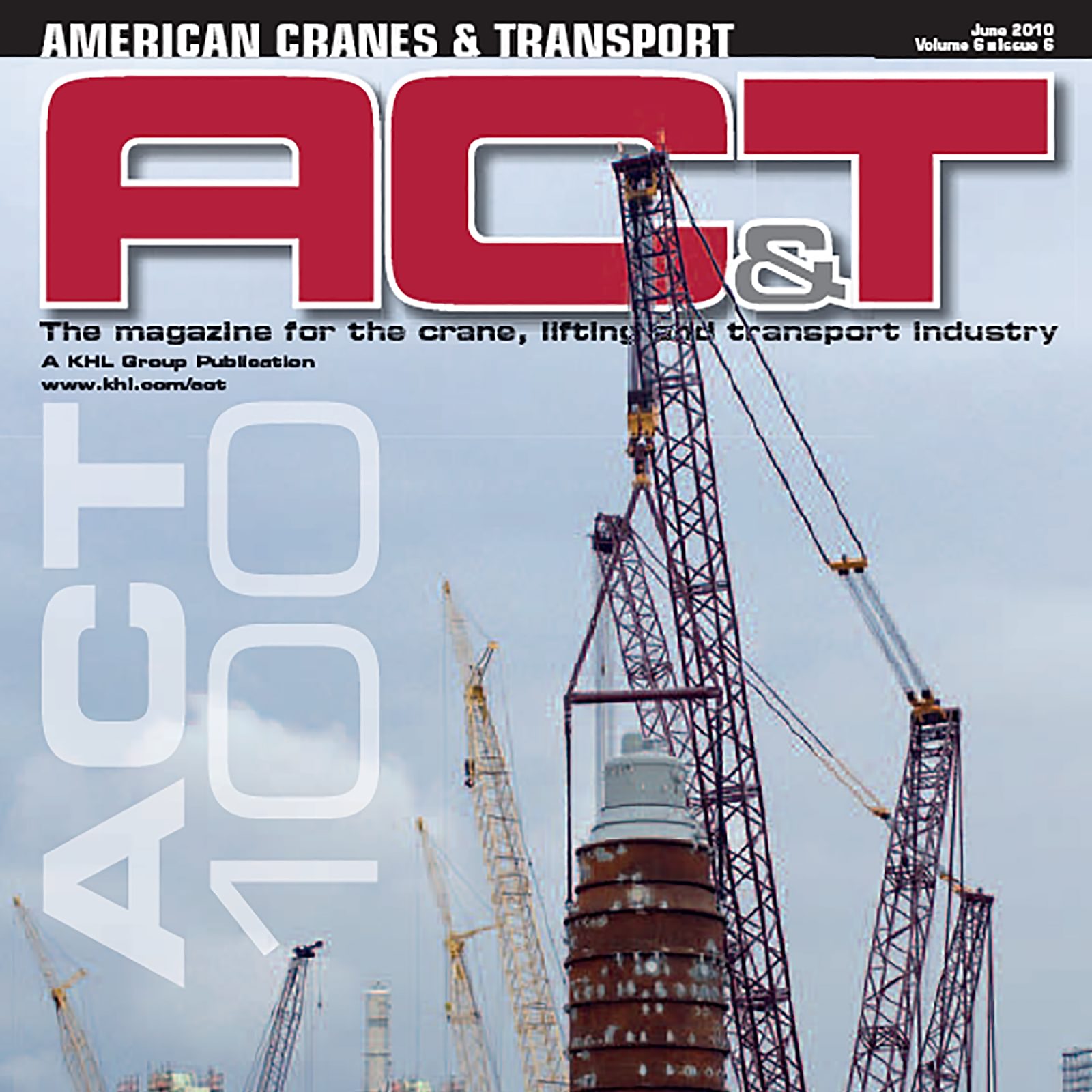

As seen in American Cranes and Transport Magazine

Transforming a 200-acre sugarcane field in Garyville, LA into a state-of-the-art refinery required a $3.8 billion investment and the work of a cadre of contractors with expertise that spanned the entire spectrum of engineering, construction, and rigging. Construction on the Marathon GME project started in March of 2007, and by December of 2009 the refinery was mechanically complete.